All British Precision provide reliable, skilled precision engineering services. Our state-of-the-art CNC machining centre enables us to manufacture a wide range of components, on-budget and on-time with ISO 9001 accreditation.

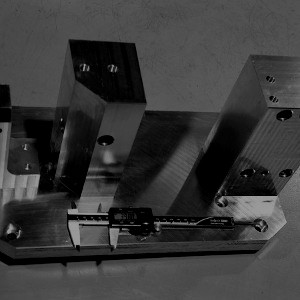

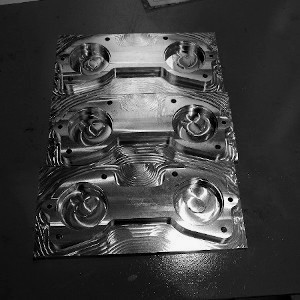

We continuously invest in the latest machine tools, including the very latest sliding head, 5 axis CNC machining centres and lathes. These are operated by our skilled team under precise process and inspection to provide the highest standards of quality and service. We have a 'right first time' attitude and that's why we earn the trust of our clients.

The latest technology supported by a team of precision engineers with multi-industry experience has enabled successful delivery of components for clients in industries including:

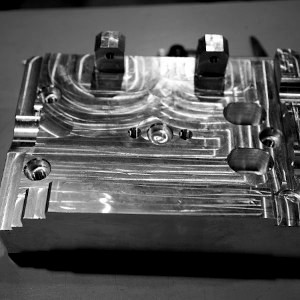

We offer flexibility for low-volume and high-volume work with urgent turnaround. All British Precision completely re-organised its facility to meet the challenge of delivering parts for the Smiths ParaPAC Plus™ machine, used to aid the breathing of those suffering from Covid-19.

As a commitment to the quality of our manufacturing process, we gained ISO 9001:2015 accreditation. We invest in our quality management systems to meet the expectations of a world-class sub-contract manufacturer.

We continually invest in new technology to enable us to meet the demand of specific industries and automate manufacture of our large-volume components. We can run 24/7, lights-out.

Our excellence in quality, turnaround and customer service has been repaid through year on year growth. Our state-of-the-art equipment, streamlined process and robotic automation means customers trust us with their critical supply chains.

A team of experienced engineers backed by major investment. We regularly increase our capabilities to meet the demands of new clients. We can manufacture in a wide range of materials including ABS, acetal, aluminium, aluminium alloy, brass, copper, mild steel, nickel alloy, nylon, plastic, polypropylene, stainless steel, and steel alloy.